Fire Research: Target Areas

Thermoset Resins

The

flammability of organic polymer matrix, fiber-reinforced

composites limits their use in commercial aircraft where

fire hazard is an important design consideration because

of restricted egress. At the present time, affordable, processable

resins for fire-resistant aircraft interiors are unavailable

since most organic polymers used for this purpose ignite

and burn readily under fuel fire exposure conditions.

The

flammability of organic polymer matrix, fiber-reinforced

composites limits their use in commercial aircraft where

fire hazard is an important design consideration because

of restricted egress. At the present time, affordable, processable

resins for fire-resistant aircraft interiors are unavailable

since most organic polymers used for this purpose ignite

and burn readily under fuel fire exposure conditions.

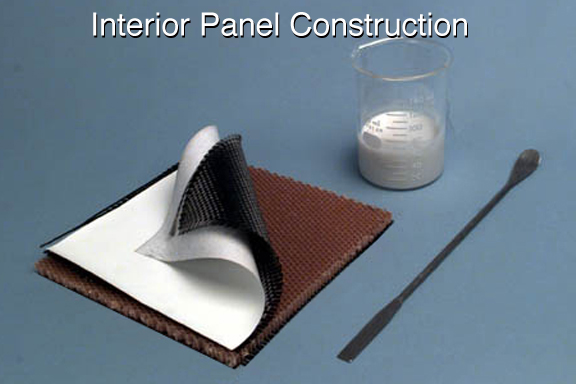

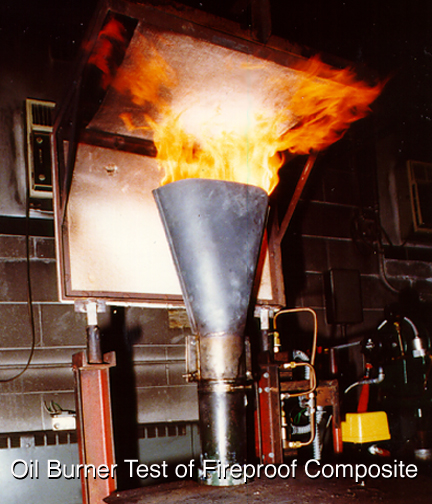

The Geopolymer resin in the beaker in the interior panel figure is being evaluated as a matrix for fireproof, fiber-reinforced composites which can be used in aircraft cabin interior panels and cargo liners. A successful cargo liner test of a Geopolymer composite is shown in Figure 2. Geopolymer is a two-part, water based, liquid inorganic (polysialate) resin which hardens at 80 degrees Centigrade (176°F) to a ceramic having twice the density of water. The fire response and mechanical properties of Geopolymer composites were measured and compared to lightweight organic matrix composites and aluminum used in aircraft.

Carbon fabric reinforced Geopolymer crossply laminates were

found to have comparable initial strength to phenolic resin

composites currently used in aircraft interiors. Unlike the

phenolic laminates however, the Geopolymer composites did

not ignite, burn, or release any heat or smoke even after

extended exposure to high heat flux. Geopolymer composites

retained sixty-seven percent of their original flexural strength

after fire exposure while organic (e.g., phenolic) composites

and aluminum had no residual strength after the test. Geopolymer

composites have higher strength and stiffness per unit weight,

higher temperature capability, and better fatigue resistance

than steel or aluminum.  Future work will

focus on understanding how Geopolymer resin protects the

carbon fibers from oxidative degradation at 800°C (1500°F)

in air, optimizing processing to obtain maximum strength,

and improving the toughness of laminated composites (Rutgers

University/FAA)

Future work will

focus on understanding how Geopolymer resin protects the

carbon fibers from oxidative degradation at 800°C (1500°F)

in air, optimizing processing to obtain maximum strength,

and improving the toughness of laminated composites (Rutgers

University/FAA)

Additional results on fire resistant resins include:

- Polybenzoxazine resins are a new, low-cost phenol-formaldehyde (phenolic) substitute for use in aircraft interior decorative panels. Polybenzoxazines have demonstrated 80% lower heat release rate, lower toxicity, and better surface finish due to the absence of volatile reaction products. A patent has been filed on this technology (Case Western Reserve University).

- A zero heat release carbon-silicon resin has been synthesized which has 97% char yield when burned. A patent has been filed on this technology (Dow Corning).

- Ethynyl polymers give off only 25 weight percent of combustible gases when burned (75% char yield). A patent has been filed on these materials. (U. South Carolina).

- A low fuel value polymer is obtained from renewable sources by reacting silica sand or rice hulls with ethylene glycol (antifreeze) in the presence of an amine base to yield semiinorganic monomers in essentially quantitative yield. Subsequent curing produces a variety of inexpensive silicon-containing polymers ranging from hard transparent films to low-density foams. A patent disclosure has been filed on this technology (U of Michigan).

- Polycyanurate resins were prepared from polystyrene and evaluated for flammability along with commercial cyanate esters (Stockton/NIST/FAA).

- Inorganic fire retardants based on zirconia and boron oxides are highly efficient, environmentally-benign additives which reduce the peak heat release rate by 60-80% in commodity (nylon, PE, polypropylene) and engineering (cyanate esters, ULTEM PEI) polymers at low concentrations without increasing smoke or carbon monoxide. A NIST patent is being filed on this technology (NIST).

Thermoplastics for Molded Parts

Commercial

transport aircraft contain between 1500 and 2500 pounds of

flammable plastics as seat trim, windows, window shades,

wire insulation, and miscellaneous parts. At present these

molded parts are not required to meet the heat release rate

regulations imposed on large area interior panels, stowage

bins, ceilings, and partitions because of their small size.

High temperature plastics which pass the heat release rate

test do not have the requisite toughness, durability, environmental

resistance, and aesthetics to function effectively in aircraft

interiors.

Commercial

transport aircraft contain between 1500 and 2500 pounds of

flammable plastics as seat trim, windows, window shades,

wire insulation, and miscellaneous parts. At present these

molded parts are not required to meet the heat release rate

regulations imposed on large area interior panels, stowage

bins, ceilings, and partitions because of their small size.

High temperature plastics which pass the heat release rate

test do not have the requisite toughness, durability, environmental

resistance, and aesthetics to function effectively in aircraft

interiors.

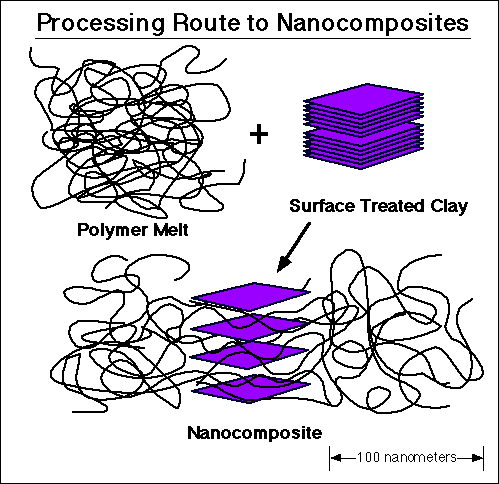

Nanocomposite technology is an entirely new generic approach

to reducing the flammability of polymeric (plastic) materials

using environmentally friendly, chemical-free additives.

The fire retardant effect of nanometer sized clay particles

in plastics was discovered by the FAA through a research

grant to Cornell University. The National Institute of Standards

and Technology (NIST) has subsequently confirmed the effect

in fire calorimeter testing. The approach is to disperse

individual, nanometer-sized, layered silicates in a molten

polymer to create a clay-plastic

³nanocomposite.² The clay particles are about the

same size as the polymer molecules themselves (less than

one millionth of an inch) so they become intimately mixed

and chemically bonded. This has the overall effect of increasing

the thermal stability and viscosity of the plastic while

reducing the transmission of fuel gases generated during

burning.

The result is a 60% to 80% reduction in the rate of heat released from a burning plastic nanocomposite containing only 5% to 10% clay by weight. This extraordinarily high degree of fire retardant efficiency comes with reduced smoke and toxic gas emissions and at no sacrifice in mechanical properties. Plastic nanocomposites have twice the stiffness and strength of the original material and a higher softening temperature (Cornell University/National Institute of Standards and Technology /NIST).

Additional results related to fire resistant thermoplastics include:

- Ultra-high modulus thermoplastic molecular composites have been tested which have low heat release rate and three times the strength and stiffness of high temperature engineering plastics (MAXDEM, Inc.).

- New phosphineoxide-polyetherimide thermoplastics have significantly lower heat release rate when burned than commercial polyetherimides (ULTEM) currently used in aircraft interiors (Virginia Polytechnic and State University, Blacksburg).

- Polycarbodiimides are carbon-nitrogen backbone polymers which can be flexible elastomers or rigid resins have been prepared from inexpensive starting materials. Polymers depolymerize cleanly to monomers with extremely low fuel value upon heating to 200°C. Molecular modeling shows that thermal stability can be increased through stereochemistry (U. of Massachusetts, Amherst).

- Novel organic-inorganic interpenetrating networks (IPN¹s) have been synthesized by separately polymerizing organic and inorganic monomers in the same reaction mixture to give a co-continuous morphology. The reaction is solvent free and the inorganic (silica) phase is atomically dispersed so that the material is transparent, rigid, and has higher thermal stability than the organic phase alone (U. of Massachusetts, Amherst).

- Surface active flame retardants concentrate at a burning polymer surface using interfacial free energy as the driving force. Migration of surface active flame retardants from the bulk to the burning surface improves flame retardant efficiency by reducing the loading level required for fire resistance (U. of Massachusetts, Amherst).

Rubber for Seat Cushions

Commercial

transport aircraft contain between 1000 and 2500 pounds of

flammable elastomers (rubber) which are foamed to make seat

cushions and pillows or used at full density as sealants

and gaskets. Foamed polyurethane rubber seat cushions are

favored for their durability and recovery but they are the

primary fire load in aircraft interiors. In 1987 the FAA

imposed regulations on the flammability of aircraft seat

cushions to delay their involvement in cabin fires. Manufacturers

responded to these regulations by wrapping the polyurethane

seat cushion in a fire-resistant barrier fabric. Seat fire

blocking allowed manufacturers to pass the FAA certification

test but the cushions burn vigorously when the fire blocking

layer is consumed after minutes of exposure to a fire.

Commercial

transport aircraft contain between 1000 and 2500 pounds of

flammable elastomers (rubber) which are foamed to make seat

cushions and pillows or used at full density as sealants

and gaskets. Foamed polyurethane rubber seat cushions are

favored for their durability and recovery but they are the

primary fire load in aircraft interiors. In 1987 the FAA

imposed regulations on the flammability of aircraft seat

cushions to delay their involvement in cabin fires. Manufacturers

responded to these regulations by wrapping the polyurethane

seat cushion in a fire-resistant barrier fabric. Seat fire

blocking allowed manufacturers to pass the FAA certification

test but the cushions burn vigorously when the fire blocking

layer is consumed after minutes of exposure to a fire.

The flammability of rubber depends on the chemical composition

of the polymer from which it is made. Rubbers made from carbon-hydrogen

based (organic) polymers are the most flammable because of

their high fuel value. Replacing carbon and hydrogen atoms

in the polymer with inorganic atoms such as chlorine, silicon,

nitrogen, sulfur, or phosphorus, results in a semi-organic

polymer with reduced flammability because of the lower fuel

value or increased heat resistance. In the Fire Resistant

Materials research program we are focusing on semiorganic

rubbers for seat cushions.

Phenyl-silicon-oxygen backbone (silphenylene) elastomers which are crosslinkable and extremely heat resistant have been synthesized. The silphenylene contains only 30% combustible material and can withstand temperatures of 600°C (1100°F) A patent is being filed on this composition of matter (U. of Massachusetts, Amherst).

Polyphosphazenes are semi-organic rubbers based on a phosphorus-nitrogen backbone which contain an organic group which allows the material to be dissolved or crosslinked. Commercial production of polyphosphazene was recently discontinued despite the extremely low toxicity and ultra fire resistance of these foams because the process for making them was prohibitively expensive. We are pursuing a new low-cost, low temperature, synthetic route to polyphosphazenes which eliminates a costly intermediate from the process and allows control over the molecular weight of the polymer. This new direct synthetic route has provided the first phosphazene copolymers including an 80-20 urethane-phosphazene copolymer which does not ignite in a flame. A patent has been filed on this process (The Pennsylvania State University).

Fibers for Carpets and Textiles

Approximately 2000 pounds of combustible textile fibers are used in a modern commercial aircraft interior as seat upholstery, decorative textiles, wall coverings, carpeting, tapestries, blankets, curtains, and seat belts. Typical fabrics include wool, nylon/wool blends, and fire retarded polyester, wool, and nylon. The chemical fire retardants added to these fibers reduce the propensity for small scale ignition but increase the smoke density and toxic gas generation once the fibers catch fire and have little or no effect on heat release rate. Our research in fibers focuses on materials with unusually high thermal stability which have intrinsic fire resistance without the need for chemical additives. Research includes:

- Zero heat release polyimide fibers are melt and solvent processable for spinning ultra high strength thermally stable fibers and casting films. Fibers of this material exhibit the lowest (microscale) heat release rate of any polymer tested to date­ ten times lower than aramid (Kevlar) fibers and 150 times lower than nylon used in seat fabrics (U. of Akron).

- Substituted polyhydroxyamides generate flame retardant compounds in a fire through a thermally-activated chemical reaction which produces a zero heat release polymer (polybenzoxazole) during heating (U. of Massachusetts, Amherst).

Federal Aviation Administration

Federal Aviation Administration