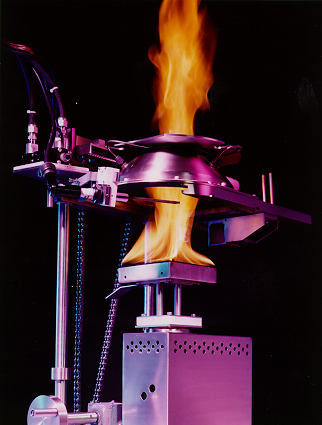

Fire Research

The Fire Safety Branch AAR-440 at the Federal Aviation Administration (FAA) Technical Center conducts long range research to develop a totally fire resistant passenger aircraft cabin with the goal of eliminating cabin fire as a cause of fatality. The Fire Research Section addresses advanced materials, fire prevention, detection, and control in a comprehensive systems approach to a fireproof cabin. The Fire Safe Materials component of the program seeks to discover the fundamental relationships between the composition and structure of materials and their behavior in aircraft cabin fires to enable the design and production of cabin materials with an order-of-magnitude reduction in fire hazard compare to current materials.

Technical Approach

The Fire Resistant Materials Program is a long-range research effort within the Department of Transportation¹s Federal Aviation Administration to develop firesafe materials for use on future commercial aircraft. The FAA Fire Resistant Materials Program goal is to eliminate burning cabin materials as a cause of death in aircraft accidents over the next ten to fifteen years. In accord with the National Research Council recommendations (13,14) for improved fire resistant materials for commercial transport aircraft, the following technical objectives were developed:

1) Discover the fundamental relationships between the

composition and structure of materials and their behavior

in fires and, using this knowledge,

2) Identify and design new materials and material combinations

which provide an order-of-magnitude improvement in aircraft

fireworthiness.

3) Develop the processing technology to ensure manufacturability

and recycleability of advanced fire safe materials.

Only when research provides adequate knowledge about the relationship between the constitution of materials and their response to the fire environment can the scientific design of functional new materials for aircraft use be successful. Aircraft materials which are targeted for upgraded fire resistance are:

- THERMOSET RESINS for interior decorative panels, secondary composites, and adhesives.

- THERMOPLASTICS for decorative facings, telecommunication equipment, passenger service units, molded seat parts, transparencies, and electrical wiring.

- TEXTILE FIBERS for upholstery, carpets, decorative murals, and, tapestries.

- ELASTOMERS (rubber) for seat cushions, pillows, and sealants.

Supporting Research will explore the solid-state burning process of materials and identify material properties which govern fire resistance. Early and direct involvement of the materials and aviation industries in the program (i.e., concurrent engineering) will facilitate Technology Transfer and provide market opportunities for fire-resistant materials outside of civil aviation (e.g., ground transportation, military, building and construction, consumer products, etc.). Expanded markets will ensure affordability and availability of new technology through market pull and result in voluntary flammability upgrades without costly regulatory burdens for the airlines.

A timeline identifying major product milestones is given in Table 1. Materials milestones in years 1999-2003 refer to the demonstration of a 50% reduction in heat release rate compared to current cabin materials when measured in laboratory- or bench-scale tests. Downselection to the most promising candidate in each category (e.g., resin, plastic, rubber, fiber) will be made over this period on the basis of functionality, cost, and potential to meeting the above fire performance guidelines. Scale-up of the most promising fire resistant materials beginning in 2004 will be required to fabricate material assemblies (e.g., decorative panels, molded parts, seat cushions, textiles) for component demonstration of zero heat release rate in years 2006-2009. Full-scale testing is scheduled for 2010 but is contingent upon the availability of program funds or commercial interest from the private sector. Milestones for Supporting Science and Technology refer to technology demonstration at the laboratory scale or in a personal computing environment. Commercialization of fire test instrumentation and analytical tools from the program will depend on private sector interest.

Federal Aviation Administration

Federal Aviation Administration