Fire Research

Problem Statement

Approximately twenty percent of the 1153 fatalities on U.S. transport airlines between 1981-1990 were caused by fire. If the aircraft fatal accident rate remains constant the total number of fire deaths will grow at an annual rate of four percent with the expected increase in commercial air passenger traffic. This is an unacceptable prospect and the FAA has taken a bilateral approach to reduce the aircraft fatal accident rate. The first approach is to prevent new factors from increasing the accident rate through programs such as Aging Aircraft, Structural Airworthiness, Engine Reliability, and Catastrophic Failure Prevention. The second approach is to reduce the number of accidents of the type that have been occurring and to increase the survivability of such accidents through programs in Airplane Crashworthiness, Cabin Safety, Fire Safety, and Fire Research.

Aircraft cabin fires fall into three general categories: ramp, inflight, and post-crash. Ramp fires occur when an aircraft is parked at the ramp during servicing. One past example was a smoldering cigarette in a trash bag which ignited an adjacent passenger seat in the unattended aircraft. To date ramp fires have resulted in the loss of property but not the loss of life. However, considering the current cost of a commercial aircraft ($100 million), ramp fires are a rare but expensive problem.

Inflight fires most often occur in accessible areas such as the galley and are detected and extinguished promptly. On rare occasions inflight fires originating in inaccessible areas become uncontrollable leading to large loss of life, e.g. a cargo compartment fire claimed all 301 occupants when fire penetrated the cabin floor and ignited seats and other materials. Inflight fire incidents are typically caused by electrical failures, overheated equipment, or improper cargo.

In the United States the vast majority of fatalities attributable to fire have occurred in post-crash fire accidents (1). Fuel fires which penetrate the passenger cabin are the primary ignition source in these accidents and it is estimated that forty percent of these fire fatalities can be attributed to smoke and toxic combustion products of burning cabin materials and jet fuel (2), with urethane seat cushions the major cabin material contributor in past accidents (3). Newer regulations require a number of fire safety improvements in aircraft cabins including materials flammability upgrades in aircraft manufactured after 1990 which, depending on the accident scenario, may extend the passenger escape time by two or more minutes in a post-crash accident involving a fuel fire. Recent full-scale aircraft fire tests indicate that further incremental improvements in material fire-resistance would do little to increase passenger escape time (4). Consequently, it is anticipated that the fire safety goal of eliminating burning cabin materials as a cause of death in aircraft accidents will require order-of-magnitude improvements in material fire resistance. In the following sections we review the types of materials found in passenger aircraft cabins and the socioeconomic factors which impact the fire performance requirements of present and future aircraft cabin materials.

Aircraft Cabin Materials

The aircraft interior is the area within the pressure hull that includes the passenger compartment, cockpit, cargo compartments, and the various accessory spaces between the passenger compartment and pressure hull. A compilation of materials used in transport category aircraft cabins, their construction, flammability requirements, and certification is published in the FAA Aircraft Materials Fire Test Handbook (5). Table 1 lists combustible cabin materials and their weight range in commercial passenger aircraft cabins (6). From Table 1 we see that there is about 7000 kg (15,000 pounds) of combustible cabin materials in an average passenger aircraft. Polymeric cabin materials have an effective heat of combustion of about 35 MJ/kg in a fire. The fire load represented by the cabin materials is therefor, 7000 kg x 35,000 kJ/kg = 2.5 x 108 kJ (2 x 108 Btu). An average aircraft carries 50,000 gallons (150,000 kg) of aviation fuel at takeoff having a heat of combustion of 43,000 kJ/kg, so that the takeoff fuel fire load is 6.5 x 109 kJ. If between 10 and 50 percent of the takeoff fuel remains at descent and landing when two thirds of the accidents occur, then the fire load represented by the cabin materials is on the order of 20 percent of the aviation fuel load at landing. This calculation shows that the fire load of the cabin materials is not insignificant in comparison to the fire load of the jet fuel in a typical post-crash accident scenario. Moreover, the location of combustible materials in the enclosed cabin environment makes the fire hazard particularly high. Carryon luggage represents an additional fireload, neglected in the calculation, which would be minimized by containment in fireproof stowage bins.

Thermoset composites form about eighty to ninety percent of the interior furnishings in today¹s commercial aircraft. Typically these composites are sandwich panels made of fiberglass-reinforced phenolic resin skins on Nomex honeycomb core which are surfaced with an adhesively-bonded poly(vinyl fluoride) decorative film or painted to provide color, texture, and cleanability. These honeycomb decorative laminates are used as ceiling panels, interior wall panels, partitions, galley structures, large cabinet walls, structural flooring, and in the construction of overhead stowage bins. Until 1986 these large-area component materials were only required to be self-extinguishing in a vertical 60 second Bunsen burner test. Recently enacted regulations based on correlation of small-scale reaction-to-fire tests and full-scale aircraft cabin fire test data by the FAA specify maximum smoke and heat release values for large-area materials in an effort to delay the cabin flashover and provide increased escape time for passengers. Cabin flashover is a non-survivable condition characterized by localized ignition of the hot smoky layer containing incomplete combustion products and rapid fire growth through the cabin interior. It is the aircraft industry¹s opinion that these stringent regulations, which required materials upgrades over a relatively short period of time, have resulted in less than optimum design solutions in many areas- the cost of which is passed along to passengers. Based on this experience there is a need for aircraft industry participation early in the current research program.

Table 1. Aircraft Cabin Materials

| Cabin Material | Kilograms Weight per Aircraft | Cabin Material | Kilograms Weight per Aircraft |

|---|---|---|---|

| Acoustical Insulation | 100-400 | Paint | 5 |

| Blankets | 20-250 | Passenger service units | 250-350 |

| Cargo Liners | >50 | Partitions and sidewalls | 100-1000 |

| Carpeting | 100-400 | Pillows | 5-70 |

| Ceiling | 600 | Thermoplastic parts | ‰ 250 |

| Curtains | 0-100 | Seat belts | 5-160 |

| Ducting | 450 | Seat cushions | 175-900 |

| Elastomers | 250 | Seat upholstery | 80-430 |

| Emergency slides | 25-500 | Seat trim | 40-200 |

| Floor panels | 70-450 | Wall covering | ‰ 50 |

| Floor coverings | 10-100 | Windows | 200-350 |

| Life rafts | 160-530 | Window shades | 100 |

| Life vests | 50-250 | Wire insulation | 150-200 |

| TOTAL COMBUSTIBLES | 3300-8400 |

The remaining 10 to 20 percent of aircraft cabin interior materials include floor coverings, textiles, draperies, upholstery, cushions, wall coverings, blankets, thermoacoustic insulation, cargo compartment liners, air ducting, trim strips, as well as molded and thermoformed plastic parts such as overhead passenger service units and seat components which are often painted to comply with aesthetic design requirements. These interior materials are not governed by the new heat release and smoke generation rules and are only required to pass a Bunsen burner ignitability test, or in the case of upholstered seat cushions and cargo liners, an oil-burner impingement test for ignitability.

Aircraft seats have been the primary fuel load in a cabin fire and are typically constructed of fire-retarded polyurethane foam encapsulated with a fire-blocking layer and covered with upholstery fabric. Prior to 1984 seating materials were required to be self-extinguishing in a vertical Bunsen burner test after 12 seconds of ignition. Since then the FAA has established an oil burner test for seat back and bottom cushions in a chair configuration which more accurately simulates real fire conditions.

The use of a fire-blocking layer material to encapsulate and delay ignition of the polyurethane foam was a practical alternative to inherently fire-resistant foam. Aramid quilts or polybenzimidazole felt/fabric are now used as fire blocking layers over fire-retarded urethane foam in passenger aircraft. These seat fire-blocking layers prevent ignition of both fire-retarded and non-fire retarded urethane foams when subjected to small to medium ignition sources such as cigarettes, newspapers, or a pint of gasoline. In simulated post crash cabin fires the seat fire-blocking layers slow fire growth and can provide 40-60 seconds of additional passenger escape time before full involvement of the seat cushions (7). Fire retardant chemicals have been added directly to the foam to reduce the vulnerability to small ignition sources. However, this approach translates into minimal fire safety improvement in real cabin fires because once ignited, a fire-retarded foam core burns readily and significantly contributes to the spread of the fire (8). Neoprene (chloroprene) foam provides a significant improvement in seat cushion fire safety at one-quarter the heat release rate of urethane although they are considered by airframe manufacturers and airlines to be unsuitable for aircraft use because of their 3-4 times higher density. New combustion-modified urethane foams pass the kerosene burner ignitability test without fire blocking layers and their use in aircraft passenger seating is increasing.

Fire Hazards of Aircraft Cabin Materials

Compartment fires in aircraft, ships, ground vehicles, and buildings are the most severe from a fire safety perspective because enclosed spaces hold heat and combustion products which increase the severity of the fire and its impact on those exposed (2). Fires in aircraft, space vehicles, ships, and submarines are particularly hazardous because of the small size of the compartments and the difficulty or impossibility of escape. In aircraft, post-crash cabin fires ignited from spilled jet fuel become life-threatening when the cabin materials become involved and the fire propagates through the cabin generating heat, smoke, and toxic decomposition products. Hot combustion products rise from the fire entraining air and forming a distinct, hot, smoky layer just below the ceiling which deepens as the fire continues to burn. The availability of air influences the products of combustion as well as the intensity of a fire. As oxygen is depleted during combustion the fraction of carbon monoxide in the smoke increases appreciably and becomes the primary toxicant in a fire. Burning panels fall and ignite seats causing total involvement of the interior. FAA full-scale aircraft cabin measurements of fire hazards- temperature, smoke, oxygen deprivation, carbon dioxide, carbon monoxide, and irritant gases such as HCl and HF- indicate that these hazards increase markedly at flashover, exceeding individual and combined tolerance limits (9) at that time. Consequently the time required to reach flashover is a measure of the time available for escape from an aircraft cabin fire.

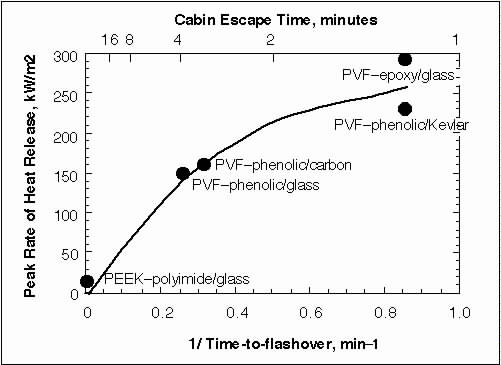

Figure 1 shows FAA data for chemical heat release rate of interior cabin materials plotted versus the reciprocal of the time-to-flashover measured in full-scale aircraft cabin fire tests. Heat release rate data are peak values from oxygen consumption calorimetry at an external heat flux of 50 kW/m2, which is representative of an external fuel fire. Samples were 6 mm thick Nomex honeycomb with resin/fiber skins of epoxy, phenolic, or polyimide resin on glass or carbon fabric reinforcements to which was adhesively bonded a 50 micron (.002 inch) thick decorative film of PVF or PEEK. Time-to-flashover data was obtained in separate full-scale aircraft cabin tests using the indicated panel materials in a realistic cabin configuration with upholstered seats and carpeting, and ignited through an open door by a kerosene fire (10). Incident heat fluxes of 50 ± 10 kW/m2 were measured near the bottom and center of the open door exposed to the kerosene pan fire (9).

The polyimide/glass skin-Nomex honeycomb sandwich with PEEK decorative film barely ignited under FAR 25.853(a-1) test conditions (35 kW/m2 irradiance) and exhibited a factor of ten lower heat release rate than conventional materials. This reduced ignitability increased the time-to-flashover (escape time) in the full scale fire tests from about 4 minutes to greater than ten minutes (no flashover was observed). Unfortunately, the ultra fire resistant PEEK/polyimide sandwich panel fabricated for demonstration purposes would be prohibitively expensive for aircraft manufacturers to purchase and manufacture at present and would not posses the durability and aesthetics needed for interior constructions. Other correlations of heat release rate with time-to-flashover of materials in enclosure fires include using the peak heat release rate divided by the time to ignition in a bench scale test, the total heat release, and the time to reach a heat release rate of one megawatt in a room-corner fire test of the same materials (11). In any case it is clear that the escape time from a burning aircraft cabin is limited by the heat release rate of the cabin materials.

Materials Fire Safety Needs for Future Aircraft

Aircraft operators and manufacturers are sensitive to cost and cost-effectiveness. Aircraft operators estimate that each pound of weight on a commercial aircraft costs between $100 to $300 in operating expenses over the service life of the aircraft. Consequently, fire safe materials for use in aircraft must be extremely lightweight. Aircraft manufacturers have made a large investment in processing equipment so that to be cost-effective new materials must be similar to previous materials in procurement costs, fabrication flexibility, scrap disposition and recycling capabilities (12-14). Fire safe materials cannot be used in aircraft no matter how desirable their properties if processing and manufacture cannot be performed efficiently and economically.

Current installed costs for aircraft materials average $300/lb, of which over sixty percent is manufacturing cost including processing and fabrication. Less than twenty percent of product cost is attributable to design, development, and analysis in a successful aircraft program. The remaining twenty percent, or $60/lb, is materials costs. The complexity of aircraft and the potentially catastrophic consequences of errors demand that part fabrication be reliable and repeatable. To implement aircraft fire safety improvements through material upgrades without regulatory intervention new materials need to deliver substantial benefits to the aircraft engineering, manufacturing, and interior design communities in addition to providing improved fire safety. The central objective in developing new materials is to deliver cost effective technology which adds value to the product manifested in improved fire safety, reduced installed part cost, and enhanced in-service performance. The speed of technology development will be facilitated by working in a collaborative environment with the aircraft and materials industries, academia, and government agencies (13-15).

As the design and analysis tools for fiber-reinforced structural composites mature over the next decade and production becomes more efficient, aircraft manufacturers will use increasing amounts of lightweight structural composites in airframes and skins to improve fuel efficiency. Future aircraft will require significant reductions in materials flammability to maintain even current cabin and airframe fire loads since the use of combustible, lightweight organic materials is expected to rise dramatically to achieve the high strength, lightweight structures and interiors required in large subsonic and advanced supersonic aircraft. Boeing projections for the structural weight fraction of polymer composites in subsonic commercial airplanes show increases from about seven percent currently to about twenty percent over the next fifteen years. The fireworthiness of these structural composites in ramp, inflight, and post-crash fires will become an issue as their usage increases because of their flammability and unique thermal- and fire-response characteristics such as anisotropic thermal conductivity (16) and persistent smoldering after flame extinguishment. Future fireworthiness problems relate to the relatively high heat release of current structural composite materials, such as carbon-fiber reinforced epoxies and bismaleimides (17), and a lack of knowledge concerning the structural performance of these materials during and after fire exposure. Fiber composites made from high-temperature resins such as poly(ether ether ketone) (PEEK), polyimide, or phenolic are more resistant to ignition at realistic fire heat fluxes (18) but suffer from low compressive strength, poor fracture toughness, and low damage tolerance related to their processing characteristics.

Semi-structural and non-structural applications of polymers and composites in cabin interiors are certain to increase in the form of passenger electronics and telecommunications equipment such as seat-mounted flat panel displays for broadcast and recorded information, FAXes, computers, and telephones, all of which will have plastic screens, housings, circuit boards, and wiring. Associated with the projected increase in passenger electronics and the recent introduction of fly-by-wire control systems is a higher risk of electrical fires in and around the passenger compartment and an increase in the consequences of these inflight fires. The current ban on the production of ozone-depleting Halon® 1211 and Halon®1301 fire suppression agents currently used for extinguishing cabin, cargo compartment, and engine fires may result in the use of less efficient agents and increased need for fire-hardened components in inaccessible areas.

Post-crash fire-hardening of cabin materials may be necessary if a proposed double-deck widebody aircraft holding 600-800 passengers is introduced by U.S. airframe manufacturers. Factors such as crowd control and overlapping of deployed evacuation slides may unexpectedly increase the evacuation time of a large aircraft in a real accident to greater than the 90 second certification requirement for escape of a full passenger load through one-half of the installed passenger exits. Consequently, human and mechanical factors peculiar to a double-deck widebody aircraft could necessitate significant materials flammability upgrades to increase the time-to-flashover of the cabin interior and provide additional time for passenger escape in a post-crash fuel fire.

The recent move in Europe to eliminate all halogen containing materials and chemicals as potential ozone depletors indicates a desire to develop halogen-free fire safe materials. Halogenated polymers and polymers modified with halogenated additives are highly resistant to ignition, particularly in synergistic combination with other additives. However once ignited, combustion of halogenated materials produces toxic acid gases (HCl, HF, HBr) which cause respiratory and eye irritation in passengers and corrosion of the aluminum airframe and electronic components (19).

A multipurpose, universal polymer system with superior fire-resistance, toughness, strength, facile processing, and recycleability needs to be developed which could be used alone or in combination as a structural composite matrix resin, adhesive, coating, fiber, and molding compound. A flammable polymer which could be used for the majority of these applications if its fire resistance was improved is epoxy. Advantages of the multipurpose polymer approach include a broad economical supplier base, redundant certification, reduced inventory, joining compatibility, processing knowledge base and design familiarity. Current activity within the aircraft industry to develop a universal fire resistant polymer centers around polyetherimide thermoplastic molding compounds for seat parts, passenger service units, and as a matrix resin for fiber-reinforced composite skins on honeycomb sidewall panels and stowage bins (20). Fire safe thermoplastic polymers have advantages over thermosets as a universal polymer such as less expensive tooling, more versatile production cycles, short process cycles, elimination of hand finishing, durability without weight penalty, integral color, pattern, and texture, recycleable materials usage, better specific fire behavior without loss of durability or appearance. Factors favoring thermosets include lower cost and the ability to use existing processing machinery and technology. The universal polymer concept is analogous to the aircraft aluminum alloy which has processing-dependent properties and obviates the need for a large inventory of different alloys and materials forms (12).

Federal Aviation Administration

Federal Aviation Administration